Ferrite Magnets

Ferrite magnets are produced using iron oxides and strontium and/or barium carbonate, they are used on a very large scale thanks to the low costs and the great availability of raw materials.

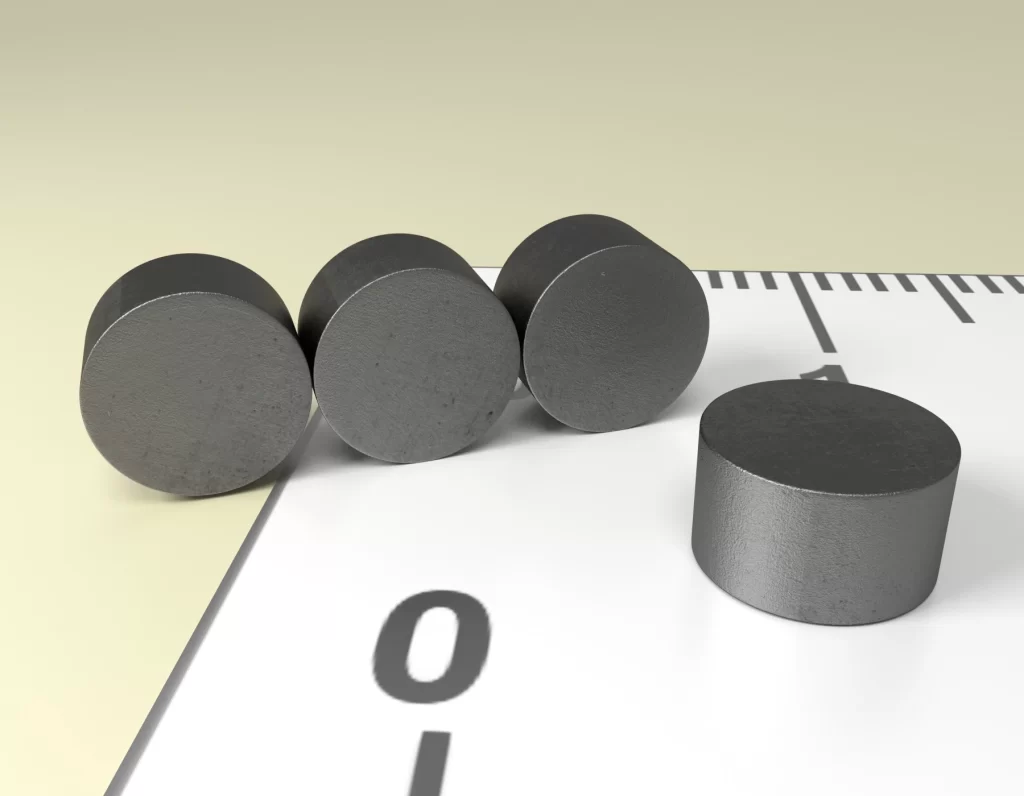

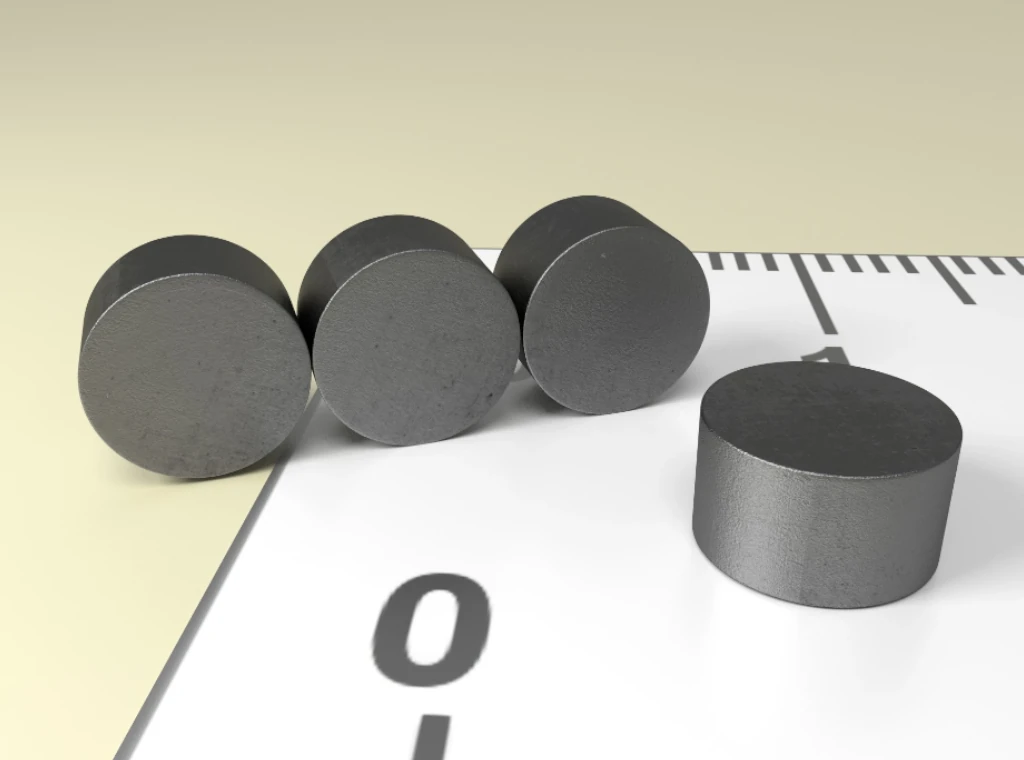

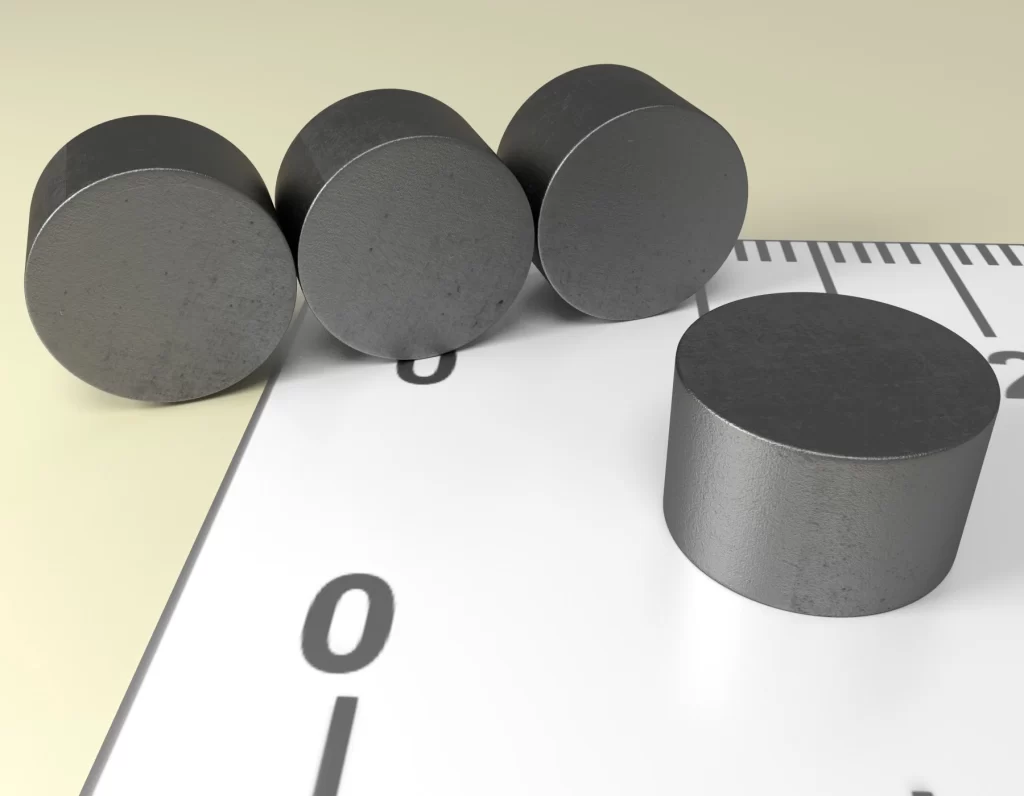

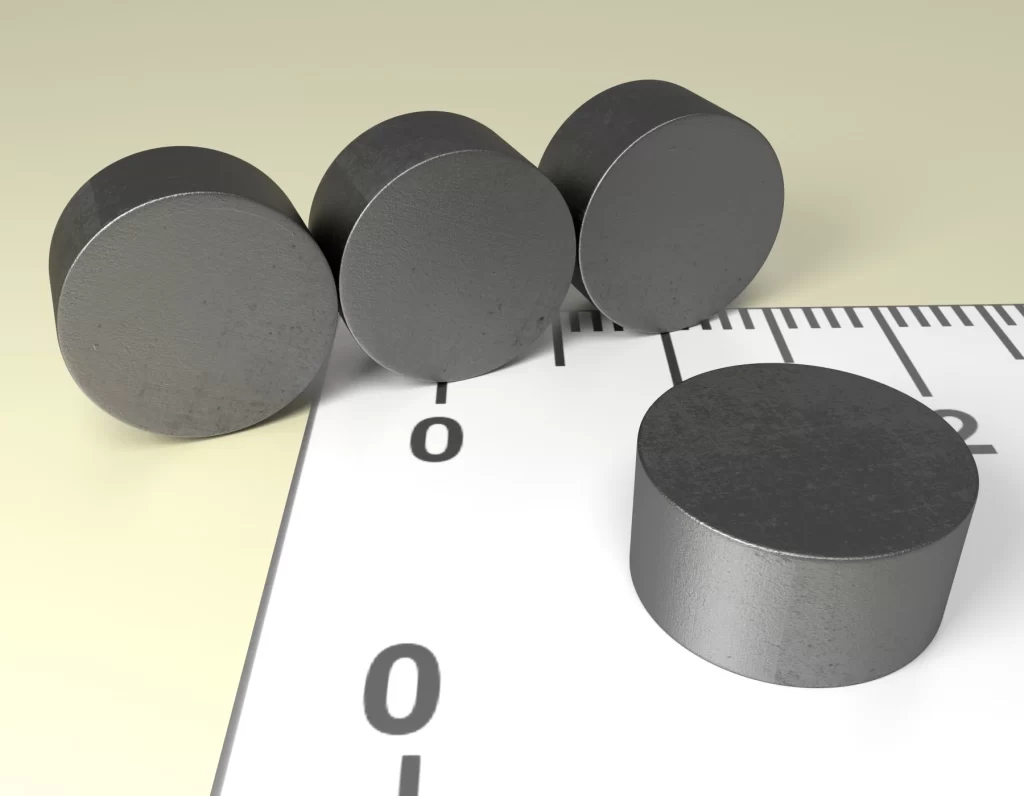

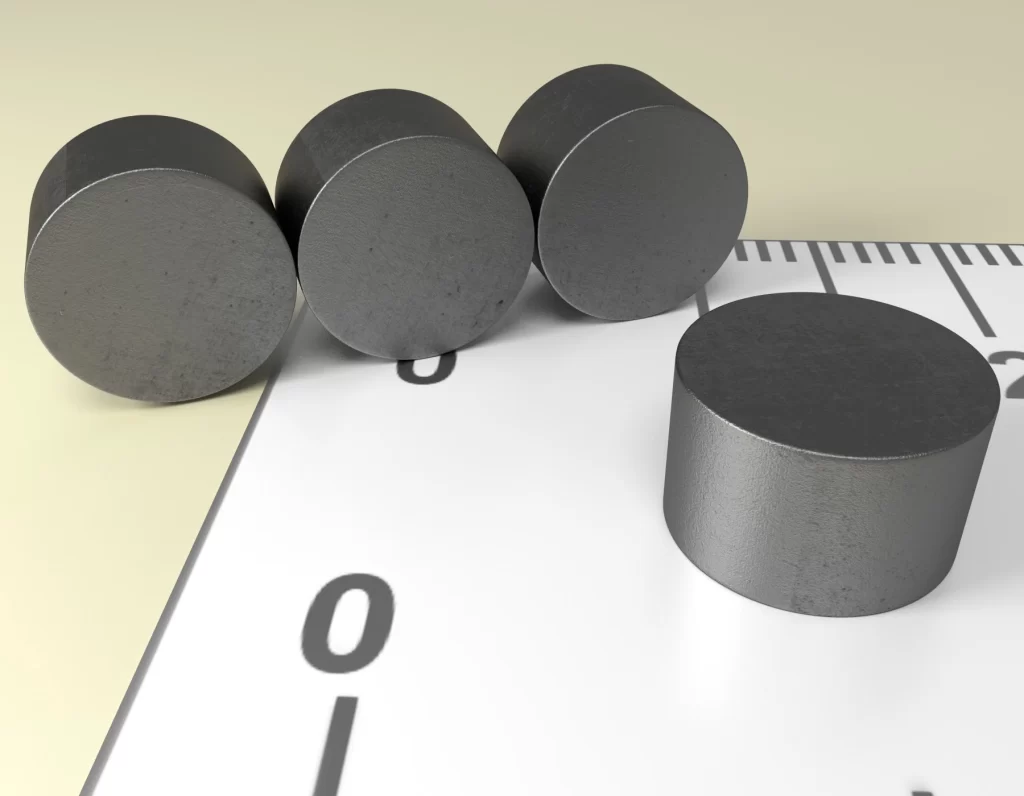

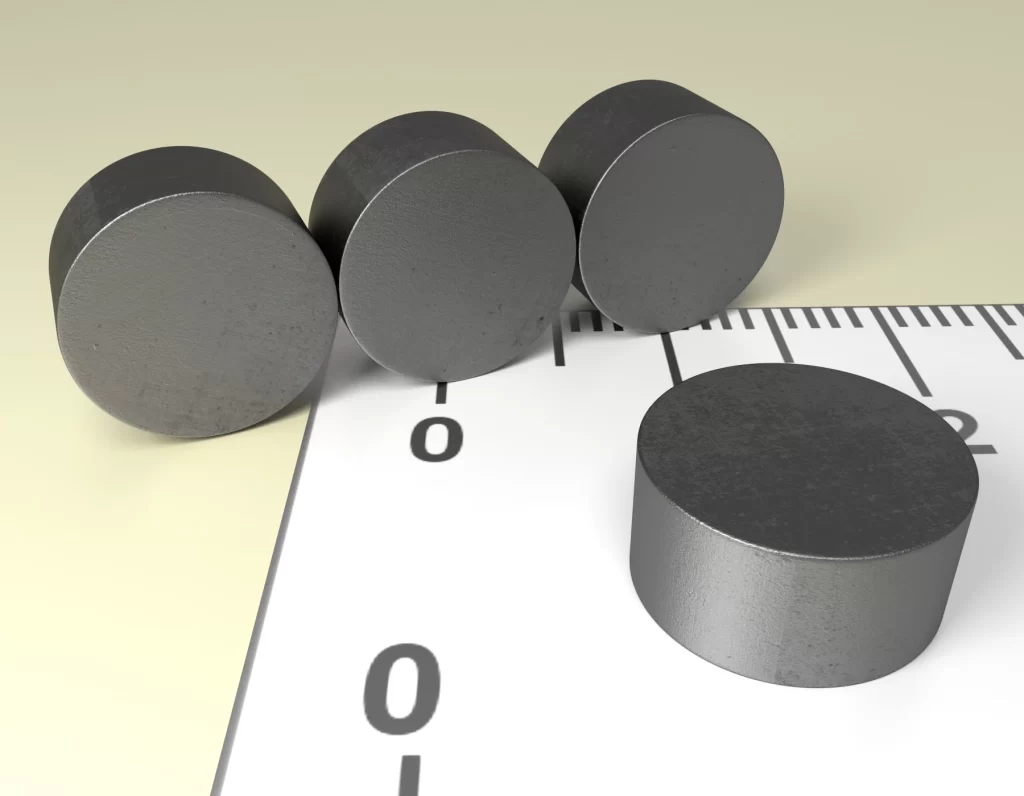

Ferrite Disc Magnet D5,2 x 3 / F30

Ferrite Disc Magnet D6 x 3,7 / F30

Ferrite Disc Magnet D8 x 2 / F30

Ferrite Disc Magnet D6 x 9,7 / F30

Ferrite Disc Magnet D10 x 2 / F30

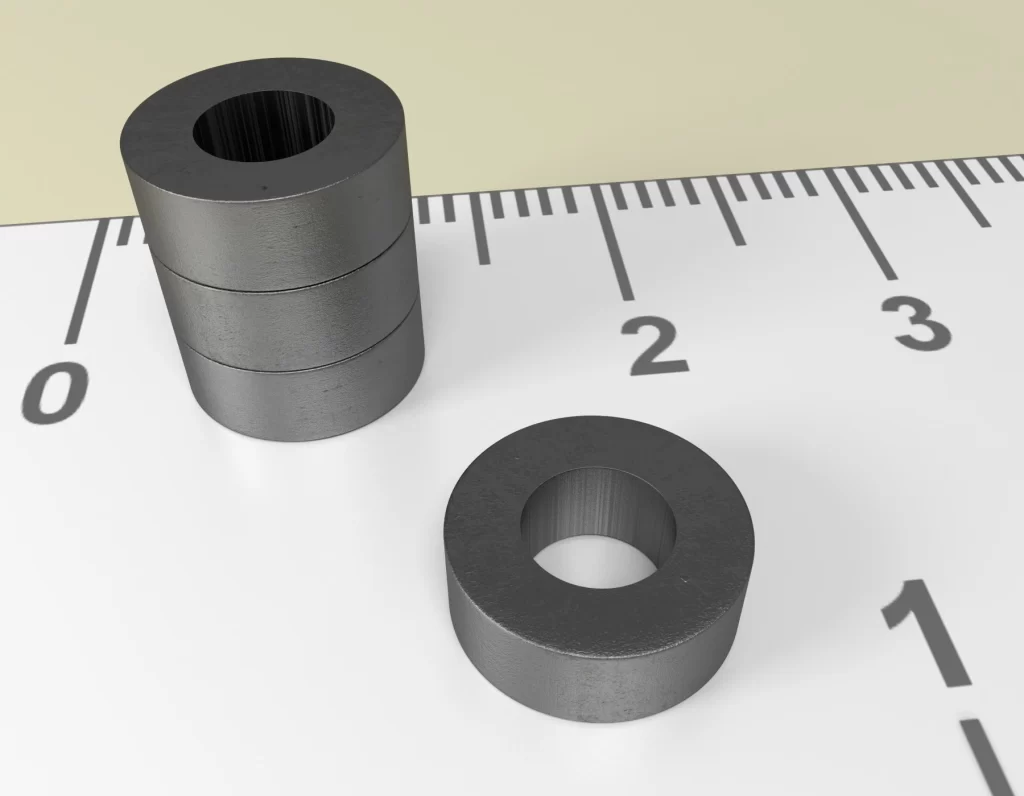

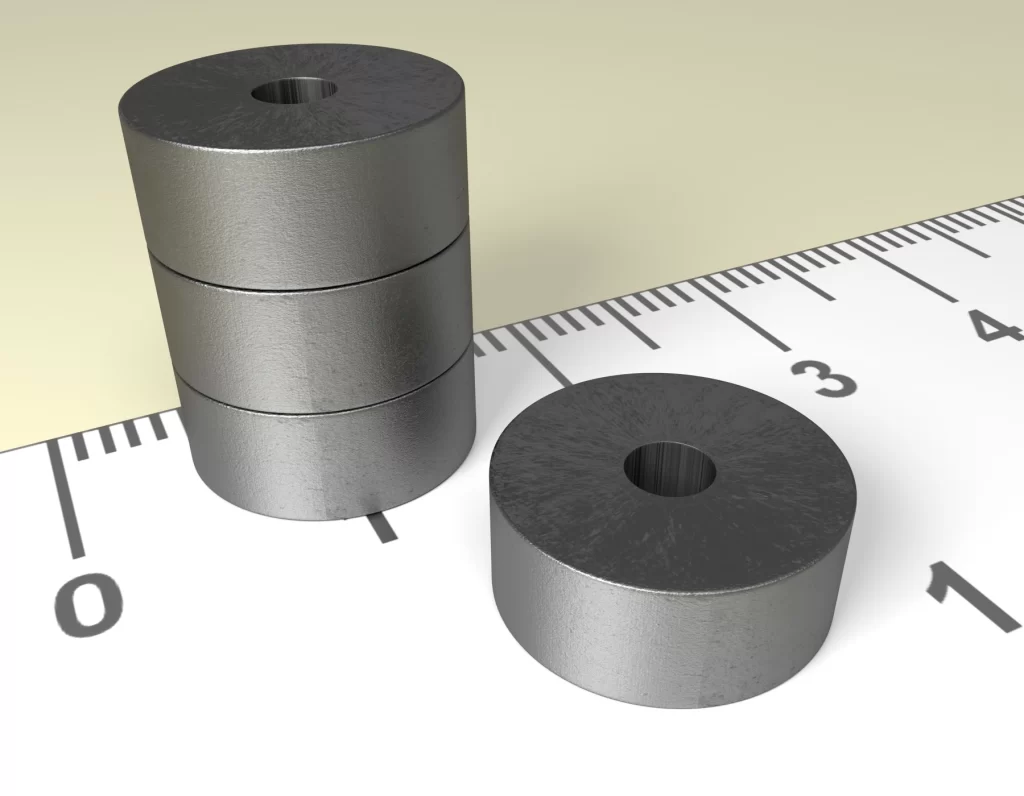

Ferrite Ring Magnet D8 X d4 X 3 / F30

Ferrite Disc Magnet D8 x 5 / F30

Ferrite Disc Magnet D20 x 2 / F30

Ferrite Disc Magnet D12 x 4 / F30

Ferrite Disc Magnet D8 x 10 / F30

Ferrite Disc Magnet D14 x 3 / F30

Ferrite Ring Magnet D11 x d2,7 x 4,5/ F30

Ferrite magnets are produced using iron oxides and strontium and/or barium carbonate. The raw materials are mixed, ground and then subjected to an appropriate heat treatment to obtain the compounds: SrFe12O19, BaFe12O19. The product thus obtained is further ground to obtain a finer powder mixture. The pressing process, which can also be done dry, is carried out both under the effect of a magnetic field and without a magnetic field. This differentiation is relevant because: in the first case anisotropic material is obtained while in the second case isotropic magnets are obtained. Finally, the material is sintered. Ferrite magnets are currently used on a very large scale thanks to the low costs and the large availability of raw material, together with the rather simple production process. A peculiarity of Ferrite magnets is their resistance to water and humidity, since it is a material derived directly from oxides it does not fear corrosion. Ferrite magnets are inherently brittle, so it is recommended that they not be used as structural elements in any application and that they be handled with care to avoid chipping.